Time: 2024-11-19 11:39 Click:

The technology of hydrogen blending and extraction in natural gas pipeline is one of the main schemes to realize large-scale long-distance hydrogen transportation, which has the advantages of large throughput and low cost. At the same time, blending hydrogen through natural gas pipelines can effectively reduce carbon emission.

RefineTek recently delivered a set of experimental membrane separation and hydrogen extraction equipment to China GRINM Group, and the end user is the State Power Investment Corporation Limited (SPIC). The membrane separation device of our company can effectively extract 5%~30%mol hydrogen in the natural gas pipeline, and the extraction efficiency is more than 95%.

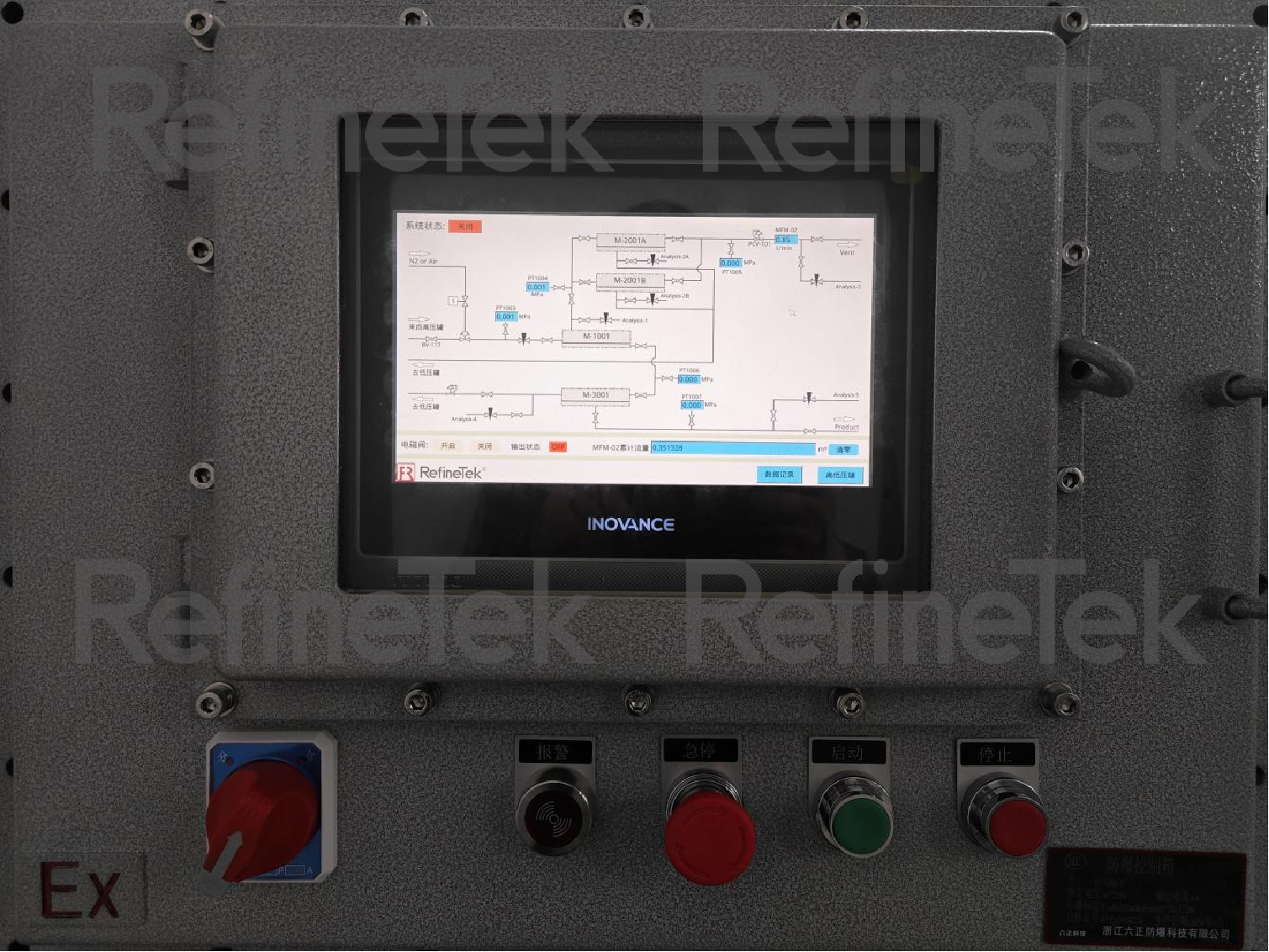

Figure 1 Field Control Interface

The relatively high concentration of hydrogen obtained through membrane separation extraction (generally up to 95%mol) is further purified to 99.999%mol (5N, grade 5) through a PSA unit, which can cover almost all downstream applications for purity requirements. If used in the field of pan-semiconductors, 5N purity hydrogen can be further purified to 99.99999%mol ~ 99.99999%mol (7N ~ 9N) by terminal purifiers (e.g., getter type, palladium tube/palladium film type, high-performance adsorbent type) to meet the harsh requirements of semiconductor processes for impurities. In the future, for the large-scale application needs of hydrogen blending and hydrogen extraction in natural gas pipelines, the company has reserved more advanced and energy-saving technologies, and is committed to promoting the development of hydrogen energy and carbon emission reduction.